Obsessing about rope

Scott Bradner

Many

years ago, long enough ago that I do not remember who, where, why or when,

someone told me that the lower ropes on clipper ships were left twisted whereas

the running rope and much of the other rope was right twisted. Since this was long before I was

involved in ship modeling, I am puzzled as to what the context might have been

for someone to tell me that. In

any case, that factoid stuck with me in the background through the years and

popped to the foreground when I started work on a model of the Donald McKay

clipper ship Flying Cloud and it set me on a quest to find out just what

the story was. This article is the

result of that quest.

Rope is not a new

concept

First of all, rope is far from a new concept. Figure 1 is of a coil of rope made from papyrus fibers from about 3,800 years ago that was found in an Egyptian cave. This rope was likely made for rigging Egyptian river boats. It looks just like the rope we use today.

Figure 1

Sizing rope

For

general background, rope on ships was sized by its circumference. Thus, a 4-inch rope is rope that has a

4” circumference (about a 1¼” diameter).

Types of rope

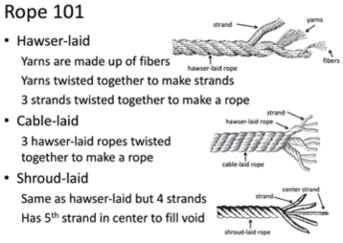

Let’s

start out with a review about the types of rope used on ships back in the day

(where “the day” was anywhere from 150 years ago to thousands of years ago). For thousands of years rope has basically

been plant material twisted into yarns, and those yarns twisted into rope. For most of this time there have been

three basic rope designs known (at least in the 1800s) as “hawser-laid,”

“cable-laid,” and “shroud-laid.” See figure 2.

Figure 2

All

of these types of rope start with fine fibers of plant material such as

hemp. These fibers are twisted

together into yarns. Multiple yarns, in turn, are then twisted together to

produce a strand.

Three

strands can be twisted together to produce a hawser-laid rope.

Four

strands can be twisted together to produce a shroud-laid rope but

when you do that you wind up with a void in the middle of the rope, so you have

to fill that void with yet another strand, a strand about half the size of the

other strands.

Four-strand

rope is a special rope that was used

for lanyards and manropes.

Four-strand rope is the same as shroud-laid rope without the center

strand.

Three

or four hawser-laid ropes can be twisted together to produce a cable-laid

rope.

Note,

that the direction of twist reverses at each stage. So, if you twist the fibers together in a clockwise

direction to produce the yarn, you would twist the yarns together in a counterclockwise

direction to make a strand and twist the strands together in a clockwise

direction to produce a rope. You

need to do this so that the tensions in the rope try to hold the rope together

rather than just let it unravel. (See, for example, Ashley[1].)

Twists.

According

to Herbert R. Carter, the number of twists per foot in a rope is inversely

proportional to its circumference and that a 2” diameter rope has 8 twists per

foot.[2] This information leads to the following

equation:

T = (6.28/C)*8

Where T is the number of

twists per foot and C is circumference of

the rope. (The value “6.28” comes from the fact that the circumference of a

rope that is 2” in diameter is 6.28”).

In researching for this article, I purchased sample lengths of many

different sizes of hemp rope and measured the number of twists per foot in each

of them. I found that the samples

closely matched the results of this equation.

I

have not been able to make scale rope that has as many twists per scale foot as

the equation calls for. The

strands break before they have been twisted enough. But I have achieved 70% or

so of the value or so for a range of scale rope sizes, and I think the result

looks good enough.

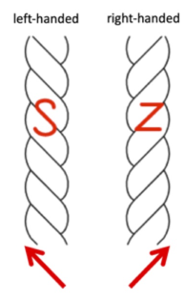

The handedness of rope.

Now

a word about the handedness of rope.

Ropes can have a right or left twist, see figure 3.

Figure 3

Most

rope on ships and for other uses has a right twist. The 3,800 year old Egyptian rope in figure 1, has a right

twist, as would any non-braded rope you might buy at the hardware store

tomorrow. That said, it turns out that some hawser-laid rope used on both

warships and clipper ships had a left twist. Cable-laid rope

made from normal right-twist hawser rope would be have a left twist. The big

question is “what rope was used for what purpose on these ships and why chose

that particular rope?”

Running rigging

A

lot of the rope on sailing ships was, and is, running rigging that goes through

blocks or is used to tie things down and needs to be flexible. Historically, almost all rope used in

running rigging on large sailing vessels was hawser-laid rope with a right

twist. Apparently, this was

because such rope was strong enough and flexible enough to do the job and last

a reasonable length of time. I say

“apparently” because I have not found any document that specifically says why hawser-laid

rope with a right twist was chosen for running rigging, but I did find a few

references that said that specific ropes, for example cannon breaching rope[3],

and the rope used for the lower and topsail yard braces on clipper ships were

hawser-laid rope with a left twist[4] because, it

was claimed, such rope was “more pliable and less likely to kink”[5],

but was not as durable than hawser-laid rope with a right twist.

Note

that most or the ropes in running rigging must be small enough in diameter that

the sailors can grasp it to haul on it and wrap it around a belaying pin, that

means that the largest practical

sized rope for running rigging is about 4.5”

(a little less than 1.5” in diameter).

Some of the rope in running rigging connects to blocks and is not

handled directly so it can be larger.

The fore and main course sail sheets & tacks are another case where hawser-laid rope with a right twist was not used. These ropes were cable-laid lines that were quite large at the sail end and then were tapered along their length so that they were small enough for sailors to handle and secure to a belaying pin at the far end.[6]

Standing rigging

The

term “standing rigging” covers shrouds, pendants, stays, backstays, lanyards

and guys as well as ratlines, foot ropes, man ropes and stirrups. The yarn to

be used in making standing rigging was treated with Stockholm Tar[7] during manufacturing[8] before being twisted into strands so that the

resulting rope would be more water resistant and longer lasting. The yarn used to make running rigging

was also tarred but to a much lesser amount.[9]

Cable-laid standing

rigging

I

started this quest to find out what types of rope were used on large sailing

vessels because I had been told at some point that the lower rigging on such

ships had a left twist where normal rope has a right twist. But neither of the most common

reference books on ships rigging (Biddlecombe & Underhill) made any mention

of using cable-laid or left twist rope for standing rigging such as shrouds.

At

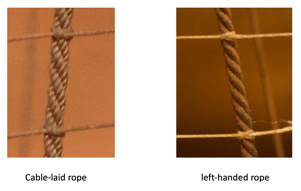

some point I noticed that the shrouds and some of the other standing rigging on

some of the ship models in the Boston Museum of Fine Arts and in the U.S. Naval Academy Museum in Annapolis were either

left twisted cable-laid rope or at least were rope with a left twist. See the

figure below:

Figure 2: Shrouds on models in the U.S. Naval Academy Museum

Specifically, there are 35 models in the U.S. Naval Academy Museum that represent large sailing

ships built before the late 1800s and are rigged. The main stays on 32 of them

have a left twist and 14 of these stays are clearly cable-laid, and the shrouds

on 13 of the 35 models have a left twist and some of these shrouds are clearly

cable laid. I was told that many

of the models had restoration work done on their rigging at some point, mostly

by one particular restorer so if that restorer thought that some standing

rigging should have a left twist that could have impacted multiple models. But some of the models, including the St

George and one or more of the prisoner models still have their original

rigging (the silk rigging on the St. George dates from about 1702!) and

these models show cable-laid stays (the St. George and the prisoner

models) and/or shrouds (the prisoner models). Thus, it was clear to me that

there was something that Biddlecombe and Underhill were not mentioning.

Figure 3: Cable-laid stay on the St George

After quite a bit of searching I located David Steel’s early

works, including the first and second editions of the Art of Rigging, Peter Forge’s Tables …, and Brady’s The

Kedge-Anchor,

all of which detailed the use of cable-laid rope in the standing rigging of

large sailing ships. Now I had proof that what I had been told was accurate and

had a lot of detail on where cable-laid rope was used. Since then, I located additional

references that help fill out additional details.

The research I undertook showed that shrouds, pendants, stays, backstays and guys on large sailing vessels were usually

cable-laid.[10] thus, they had a left twist.

For

example, the figure below shows a shroud and deadeye from the HMS Invincible

which sank in 1758. The rope is

cable-laid with a left twist.

Figure 4: Shroud and deadeye from HMS Invincible

But

why would ship builders decide to use cable-laid rope for the shrouds,

pendants, stays, backstays and guys

on big sailing ships? For very large

shrouds and stays the answer is easy, the rope making processes of the day

could not reliably make hawser-laid rope larger than 9” in circumference, due to difficulties in keeping yarn tensions even.[11]

But this is a reasonable question for smaller rope. Those contemporaneous documents that discuss the use of cable-laid rope, point out that cable-laid rope is weaker than hawser-laid, but it seems that the mariners of old thought that cable-laid rope was watertight. For example, see this quote from Luce’s 1863 Seamanship:

Cable-laid … Rope, …, is left handed rope of nine strands and is so made to render

it impervious to water, but the additional twist necessary to lay it up seems

to detract from the strength of the fibre, the strength of plain laid being to

that of cable-laid as 8.7 to 6; besides this, it stretches considerably under

strain.[12]

It may or not have been the case that

cable-laid rope was more “impervious to water” than hawser-laid rope but

the fact that it was a widely assumed feature would lead shipbuilders to use

cable-laid rope for standing rigging, where they did not want to have to

replace it as often as they replaced running rigging rope. The logic seems to have been: if using

cable-laid rope kept the water out maybe the rope would rot less and thus last

longer.

In

any case, cable-laid rope was in common use as late as 1909, as is shown in the

following quote from H.R. Carter:

Ropes

from 1 to 2 ½ inches in circumference are usually hawser-laid, and from

3 to 10 inches either hawser- or cable-laid. Above 10 inches they are always cable-laid.[13]

The conclusion that most if not all of the

shrouds, pendants, stays, backstays and guys on ships like the Flying Cloud were cable-laid is reenforced by the rigging tables

in many references that included the types of rope used on sailing ships around

the time that the Flying Cloud

was active. (See endnote 10.)

As mentioned above, cable-laid rope can be

made of 3 or 4 hawser-laid ropes.

Duncan McLean wrote that the standing rigging on a number of the Donald

McKay clipper ships, built and launched around the time that the Flying

Cloud was launched, was made up of “four-stranded patent rope of Russian

hemp[14].” I assume McLean meant cable-laid rope

made up of 4 hawser-laid ropes, although it is possible that he might have

meant shroud-laid rope. I think

the letter is unlikely since it would contradict the many references that

insist that most standing rigging was cable-laid, particularly since at least

the lower shrouds and stays were larger than what could be achieved in

hawser-laid rope. In

addition, the routing tables for merchant ships in the early editions of

Steel’s The Art of Rigging show cabled 4-strand rope for stays,

backstays and shrouds.[15]

Lanyards

Lanyards

used with deadeyes were made of four-stranded, tarred, hawser-laid rope.[16]

Footropes, manropes, Flemish horses and stirrups

Footropes

(old name “horses”) hang below the yards to support sailors working on the

sails, footropes are supported by stirrups if they span a wide enough space,

Flemish horses are short footropes that overlap the base footropes to reach the

ends of the yards, and manropes are strung alongside booms, etc. to provide a

handhold.[17]

I did not find any references that said what type of rope was used for footropes,

stirrups and Flemish horses, so I have assumed that they were tarred

hawser-laid roped with a right twist.

Manropes

were tarred 4-strand rope like lanyards.[18]

Ratlines

Ratlines

were tied across shrouds to enable sailors to reach the yards and upper masts. Ratlines were generally 1 to 1.5 inch

rope and thus, too small to be cabled. I did not find any references that said

what type of rope was used for ratlines, so I have assumed that they were

tarred hawser-laid rope with a right twist.

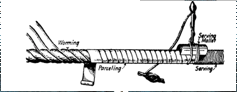

Worming, parcelling and serving shrouds

Worming

is wrapping a small rope into the spiral groves in a large rope to make the

rope’s surface smoother. Parcelling is wrapping strips of canvas around a rope

in a spiral fashion and tarring the result thus sealing in the worming rope. Serving

is tightly winding a small tarred rope around a parcelled rope to create a

barrier to chafing such as by sails.[19]

Figure 5: Worming, parcelling

and serving a rope

Shrouds

are wormed, parcelled and served where they go around a mast.[20]

Also, the full length of the foremost shroud of each set of shrouds is wormed, parcelled

and served to protect it from the rubbing of the sails.[21]

Sizes of deadeyes, lanyards and blocks

Here

is some other rigging-related sizing information I found in my research.

The

diameter of a deadeye is 1.5 times the circumference of the shroud or

other rope that it will be used with.[22] This matches the information in those

rigging tables that include deadeye sizes.

The

size of a lanyard in a deadeye is half the size of the shroud or other rope

that the deadeye will be used with.[23] This

matches the information in those rigging tables that include lanyard sizes.

Blocks

are sized based on the size of the rope that will run through them.

Specifically, the thickness of the sheave in the block is 1.1 times the

diameter of the rope, the diameter of the sheave is 5 times the thickness of

the sheave, the slot for the sheave is the thickness of the sheave plus 1/16”,

the length of the block is 8 times the width of the sheave slot, the width of

the block is 6 times the thickness of the sheave, and the thickness of the

block is ½ the length of the block.[24]

Thus, the length of a block (what is often

referred to as the size of the block) can be expressed in the following

equation:

L = ((D * 1.1) + 1/16) * 8

Where L is block length and D is the rope

diameter.

Overall,

single blocks are about ¾ as thick as they are long and half as wide as

they are long. Double and triple

blocks are wider.

For my Flying Cloud model

After all the research, I decided to use

natural color hawser-laid rope with a right twist for all of the running

rigging except for a few yard braces - which will be natural color hawser-laid

rope with a left twist, and the course sheets and the course sheet tacks

– which will be natural color tapered cable-laid with a right twist (if I

can figure out how to make tapered cable-laid rope).

I also decided to use dark brown/black 4-strand

cable-laid rope for the shrouds, stays, backstays and guys; black/brown

4-strand hawser-laid rope for the lanyards, and black/brown 3-strand

hawser-laid rope for the rest of the standing rigging, including foot ropes,

ratlines, etc.

An

earlier version of this article was published in the April 2020 issue of the USSCMSG Broadside.

photo

credits:

figure

1: https://www.bu.edu/cas/magazine/fall10/Egypt/index.shtml

figures

2 & 3: photos by author

figure

4: forgotten source related to the HMS

Invincible

figure 5: https://www.hmsrichmond.org/knots.htm

6/17/2021